Components

|

The best mail-order source of electronic components for a

hobbyist in the US is

Mouser Electronics.

They have no minimum on purchase and they charge for shipping

only once when there is a backorder. They were my primary

source. My secondary sources were

Newark Electronics, a local

electronics store and a local Radio Shack. Newark charges

separate shipping for every backorder and they are quite

indiscriminate in that. You end up receiving multiple (can be

10) shipments

of parts valued e.g. at 20c or 50c and $3.50 shipping charges

tacked

on top of those. If you order from Newark, make sure that you

disallow the backorders.

|

Circuit Board

|

I decided to move the power transistor, driven by the Maxim

chip, out of the board and to attach it to the circuit housing

letting the housing to serve as a heat sink. Moreover, I

decided to use Molex (alternative are AMP) wire to board

connectors for the connections to the transistor, adapter

socket, switch, the two LEDs, batteries, dynamo and light.

Finally, the

three chips and two relays were to be placed in sockets. The

purpose was to have sufficient flexibility in what was to be

an experimental design.

|

|

For a general discussion of the printed

circuit boards see the

site of Harry Lythall.

I decided to go with a double sided board. First, I designed

the layout on a 0.1" grid paper. While designing, I was

inserting the components into a 0.1" perforated board testing

how the layout was playing out. The size of the board I ended

up adopting was 2_5/8 x 2_1/8". Following Harry's suggestion,

I used the grid paper layout to mark holes on still another

perforated board. That board I clamped together with the

copper

clad board to drill holes.

Note: you should drill

the holes from bottom up as the copper sticks out from the

board in the direction of drilling, in the immediate vicinity

of a hole. Regrettably, I did not follow this rule as may be

apparent in the enclosed photographs. Upon drilling holes in

the clad board, I marked

connections with an etch resistant pen.

Etching was a relatively easy

process.

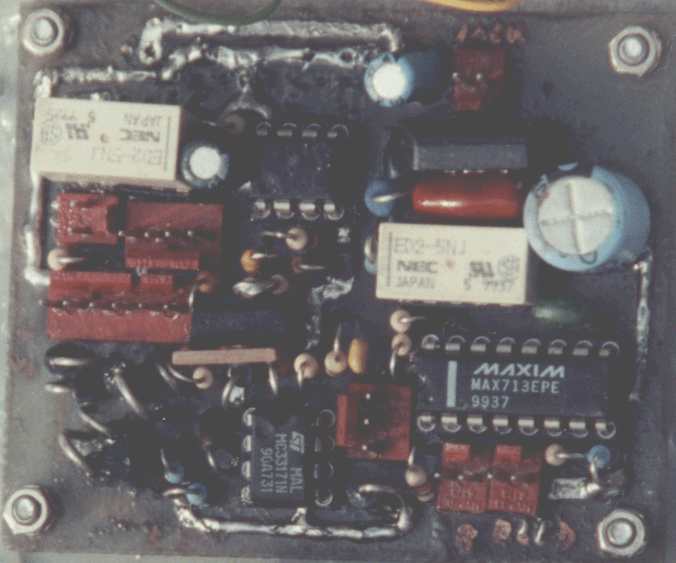

The designing of the layout turned out to take far more time than I expected, in fact a fortnight worth of evenings or so. The shown design was developed for the first version of the circuit. The charger circuit around MAX713 occupies the right side of the board. The protective part of the circuit, eventually removed, was placed in the upper left horizontal strip, as looked from above. The rest has been devoted to the core regulator circuit. If the charger circuit were to be dropped, the board could be significantly reduced in size. Have I thought more, I would have realized that the top of the board connections work when the component has its terminal exposed above the board. This is in particular not true for chip sockets. Thus I ended up with some wire connections. In addition, I needed to add an RC snubber, indicated in the schematic, connecting the terminals of the second op-amp, that ended up below the board. The finished board is shown in the adjacent photograph. For protection from the weather influence I covered the board, from both sides, with a silicon conformal coating. When spraying the coating, it is essential to protect the connectors. From above, you may just spray so that the coating spreads underneath the components. The Molex connectors I used stick out quite a bit from the board. That is convenient for plugging them in and unplugging but otherwise wastes space. My first connector choice was JST but they were unavailable within retail in the US. |

|

|

|